About

International Energy Services Limited (IESL), established in 1990 is an indigenous energy services company currently providing integrated clients-focused and cost-effective services in the oil and gas industry with specialized expertise for both onshore and offshore developments. IESL has assembled a highly qualified team of professionals with worldwide experience and capability to provide practical solutions to complex problems at all phases of energy, oil and gas engineering projects.

International Energy Services Limited (IESL) works in close collaboration with Clients from projects conception to completion, and offer world-class solutions to their needs. It structures its operations into strategic business divisions to further improve service delivery, thereby meeting Client’s high standard for sustainable quality and confidence. IESL is involved in Engineering Designs (Basic, FEED, and Detailed), FPSO Topsides, Pipelines, and PRMS, Oil & Gas Platforms and Facilities, Project Management & Inspection Services, Engineering Technical Services, Maintenance, Procurement, Construction and Contracting Services, Environmental/Analytical Laboratory, QHSE Consultancy Services, Solar & Power Engineering Services. The company is also currently involved in Effluent Monitoring, Gas Sampling and Analysis, Corrosion Management of crude and gas lines, Environmental Audit, Solar Energy Design and Installation, Technical Manpower Supply and Training, as well as Logistics Services.

IESL has strategic alliance agreements with reputable international Consulting, Engineering and Inspection firms within and outside the country. From these alliances, IESL brings together an integrated range of multi-disciplinary, skilful and highly professional engineering, technical and administrative personnel from different backgrounds offering synergy and time vantage solutions for the energy industry.

This also gives the technical skills and state-of-the-art computing technology to consistently provide solutions for a diverse range of problems.

Our Mission

• Achieve excellent quality of services

• Operate our business in an efficient, enterprising, safe, and innovative manner.

• Create value for our shareholders, clients, and employees.

• Protect our clients' right to privacy and confidentiality

• Recognize our accountability to our community, industry peers, the public and ourselves.

Our mission is fundamentally predicated on honouring these responsibilities in all our work, in accordance with the unifying principles, which we share.

Our Vision

Employing human and material resources for energy services delivery as a world-class company with highest standard of efficiency and integrity.

Our Goal

To achieve and maintain a leadership position as a world class engineering and consultancy company, known and respected for the quality of our work and the character of our staff.

We are continuously:

• Striving for Excellence

• Dedicated to Service

• Committed to Values

• Motivated by Accomplishment

Our Values

At IESL, we believe in creating and providing solutions. We feel that every man-hour spent should make you money and give satisfaction. We focus on results. To do that, we believe in hiring - and keeping - good people, people who strive not just to do a good job, but also to do what's right, ethical and good for our clients. Our company’s goal is to continue building our reputation as a world-class engineering and consultancy firm, known and respected for the quality of our work and the character of our staff. We do this discretely, protecting our clients' right to privacy and confidentiality. You can count on us to help you reach the best solution.

These values are underscored by our General Business Principles:

Our General Business Principles

Recognition as a company that gives equal opportunity to all Nigerians from all States of the Federation, with due regard given to excellence and merit.

- Recognition as a company that can be relied upon and that provides good services.

- Recognition as a company that achieves superior performance in all its ramifications by fully utilizing the creativity of its employees, financial and technical resources and all its physical assets.

- Recognition as a company that provides a safe and satisfying work environment, to foster and encourage highly motivated and team-oriented employees who will contribute to our growth.

- Recognition as an innovative company, constantly seeking improvement; utilizing and developing appropriate and modern technology at all levels.

- Recognition as a company that conducts its business with high regard to health, safety, environment and sustainable development.

Quality Policy

International Energy Services Limited (IESL) Management is totally committed to achieving the highest quality standard with the co-operation of all employees in achieving this goal. The philosophy is towards achieving high-level Client’s satisfaction and high quality services. We always ensure that our activities for project realization are in line with international standard that fully meet or surpass our client’s expectation and requirements in terms of quality, cost, and delivery schedule.

IESL strives to achieve this through the effective implementation of a Quality Management System (QMS) with basic focus on the following objectives:

• Implementing a Quality Management System and processes that enhance compliance with international standards, Client’s regulation and statutory requirements.

• Being Client’s focused in all aspect of our operations, service delivery and product development.

• Regular review of products, processes, and operational framework based on (internal and external) customer feedback with a view to ensuring continual improvement.

• Developing robust business and efficient processes with supporting documentation and controls.

• Consistently and effectively managing our business risks and increase our profitability through consistent application of our rules, guidelines, procedures, and lessons learnt

• IESL also takes and accepts responsibility for the quality of its services and sub-contractors.

• All the top management of IESL is responsible for compliance with this Policy.

Corporate Structure

IESL currently has six operational divisions; Engineering Design, Project Management, Inspection/Technical Services, Solar & Power Engineering, QHSE Consultancy/Analytical Laboratory Services and Corporate Recruitment & Training. Their operational structures and activities optimized in order to best serve our customer base. Although each division has a unique manager, he is at liberty to draw upon the wealth of capability throughout the organization, irrespective of divisional boundaries. This flexibility enables managers to assemble the best and most appropriate team for each client’s specific requirements.

Engineering Design Services

IESL currently has about 180 workstations for engineering design activities, manned by Engineers of different disciplines with experience spanning between three and 18 years, and specialize in Oil & Gas engineering design.

IESL can provide the complete engineering of oil and gas field development, from conceptual studies to detailed engineering including procurement, technical assistance and supervision.

Conceptual/Feasibility Studies

IESL performs feasibility studies to determine optimal design/cost considerations for the development and transportation of oil and gas resources. These studies usually include:

• Determination of technical alternatives

• Overall route and system optimization, including profile and hydraulic study

• Estimation of capital cost and operating costs

• Definition of the main features and functional requirements of the project.

• Investment appraisal and economic evaluation

• Recommendation of preferred solution (with economic considerations and benefits)

FEED/ Basic Engineering

IESL has the capability to produce basic engineering designs and followed these through to the preparation of tender documents and the evaluation of bids for a large number of pipelines. The scope of IESL’s work typically includes:

• Process design

• Technical dossier (specifications, calculation notes, general drawings) incorporated in the call to tender for turnkey contracts and long lead items supply.

• Evaluation of tenders.

Minor Modification – Applicable for Onshore/Offshore

IESL has experienced engineers with capability to perform minor modifications (Re-design & Follow-up reconstruction) of existing facilities in offshore/onshore installations.

Detailed Engineering

IESL has performed this role on many major projects. IESL is currently undertaking two major offshore projects with technical support from Doris Engineering, Paris. The projects are OFON 2 Topside Design and USAN FPSO Detailed Engineering Design. The involvement is determined by the type and scope of the project with the services provided frequently including:

Process Facilities

IESL provides mechanical engineering services for all phases of oil & gas processing. Our comprehensive capabilities allow us to provide design services for every process system required on an offshore platform.

This diverse experience has led to the effective design of projects ranging from oil and gas processing and gas compression, to pipeline terminals, dehydration systems, and enhanced recovery systems.

An extensive background in vessel sizing and design, production equipment packaging and interconnecting piping design, further strengthens our ability to deliver the highest standard of service on an unparalleled timeline.

Optimum efficiency, productivity and compliance are fundamental to the design of all process facilities, resulting in successful permitting. In every project, IESL achieves these goals as an integral part of the overall design function.

A thorough knowledge of HAZOP and SEMP requirements ensures that our designs not only comply with government-required procedures, but also allows operators of existing platforms to upgrade facilities for compliance. With IESL vast experience, achieving compliance is never an issue.

Electrical Design and Operability Analyses

System design utilizing Electrical Transient Analysis Program (ETAP) for:

• Load and Power Analysis

• Short Circuit Analysis

• Protective Device Coordination Analysis

• Generator/Utility modelling/sizing

• Transmission line modelling

• Motor Starting modelling

• Cable sizing routing and tray/duct bank/vault Analysis

• Transient System Analysis

• Harmonic Analysis

Fire & Gas Design and Operability Analyses

Conceptual and operational Fire & Gas System design:

• Specifications.

• System design and procurement

• Field installation and operational inspection

• Test & Commissioning

Instrumentation

When a project calls for instrumentation, IESL designs a variety of pneumatic/electronic control & safety systems--such as emergency shut down (ESD), waterflood and steamflood facilities, platform safety, subsea completion, and compression control.

IESL produces all drawings and reports required to ensure that control systems meet government standards and procedures, including responses to MOC (management of change) documents, safe charts for functional analysis and evaluation, and permitting packages (MMS).

Our engineers also perform field surveys to evaluate existing systems, verifying that the system complies with industry safety standards--such as the American Petroleum Institute (APl) RP14C and RP75. Following evaluation, we recommend and implement the required system changes to ensure compliance.

Years of experience and refined work methods help to reduce the cost and time in designing and constructing control & safety systems. Whether we are designing new systems or evaluating existing ones, safety always comes first.

Structural Design

Fixed Offshore Structure Design

Caissons and Braced Caissons

Wellhead or Well Protector Platforms

Production Platforms; Jackets and Decks

Modules

Offshore Structure Installation Design

Loadout Analysis

Transportation Analysis and Tie-Down Design

Lift Analysis and Lifting Eye Design

Flotation Analysis

Jacket Upending Analysis

Pile Driveability Analysis

Installation Rigging Design

Installation Appurtenance Design;

Bear Clamps, Spreader Bars, etc.

Platform Assessments

Damage Assessment

Assessment for Increased Platform Loading, Additions

Repair Procedure Development

Pile Design for Prefabricated Decks

Steel

Timber

Compressor Vibration Analysis and Stiffening Design

Appurtenance Design

Boat landings

Riser Guards

Deck Extensions

Conductor Additions. Helipads

Drilling Templates

Process Equipment Skid Design

Subsea Template Design

Third Party Verification (CVA)

Pipeline Design Assistance

Laydown Sleds (PLEM/PLES Design)

Anchors and Anchor Clamps, including SCR Anchor Clamps

Helical Strake Arrestor Clamp

Net Guards

Land Based Facility Design

Equipment and Building Foundations

Tank Foundations, Ringwall Design

Pipe Supports

Civil Design

Retaining Walls

Drainage

Small Buildings

Vessel Design

Hull Design

Lay Barge Stinger Design

Tensioner Machine Support Design

Reel Design and Reel Skidding Design, FEA Design

Vessel Appurtenance Design

Vessel/Barge Strengthening Design

Production Equipment Support Frame for FPSO’s.

Offshore/Onshore Pipeline Services

Pipeline Design

Conceptual Design

Cost Estimating

Permitting

Detailed Design of Pipelines

Routing

On-Bottom Stability

Cathodic Protection

Pipeline Crossings

Materials

Spanning Analysis

Deepwater Design

Detailed Design of Riser Systems

Conventional Risers

Steel Catenary Risers

J-Tube Risers

Consulting

Hydraulic Analysis/Optimization (Oil, Gas and Multiphase Flow)

Right-of-Way Coordination and Permitting

Line Sizing

Installation Stress Analysis (Onshore and Offshore)

Specification Development

Materials

Construction

Pipeline Related Facilities

Pump Station Design

Launcher’s/Receivers

Oil and Gas Metering.

Project Management Services

The strength of our project management capabilities begins with experienced people. From mechanical, electrical, pipeline, controls, structural, industrial, and petroleum engineers, to specialty engineering designers and field support personnel, the IESL staff include some of the industry's most talented professionals - respected for their team work, as well as individual expertise.

IESL Project Managers run and execute projects of all sizes. From concept to completion, our engineers have extensive knowledge of and experience in project development, execution and management. Known for high-accuracy, IESL helps to reduce construction time and the cost of fabrication for facilities and components - without compromising safety and quality. The high degree of service we provide is the result of an astute understanding of the construction process acquired from years of hands-on experience with fabricators.

When projects require fast-track status, we ensure that deadlines are met by providing on-site construction management. Our diverse experience, coupled with an extensive project library, allows IESL teams to respond quickly, providing significant savings in cost and time.

Our services include but not limited to the following:

Project Management

• Development of Preliminary Design Concept

• Preparation of Project Schedule

• Cost Schedule Status Reporting

• Work Breakdown Structure

• Development of Detail Design

• Performing of Process Hazard Analysis (HAZOP)

• Interface with Outside Engineering and Construction Contractors

Documentation, Purchasing and Material Expediting

• Material Sourcing

• Vendor Qualification

• Bid Package Preparation

• Bid Evaluation and Vendor Recommendation

• Purchase Orders

• Expediting

• QA/QC Procedures and Documentation

• Material Management

• Invoice Approval

• Interface w/ Client Management and Accounting

• Pre-commissioning and Commissioning Procedures

• Vendor Data Books and Operational Manuals

• As-Built Documentation Preparation.

Construction Management and Supervision

• Preparation of Project Schedule

• Cost Schedule Status Reporting

• Transportation and Logistics Coordination

• Factory Acceptance Testing (FAT) Coordination and Supervision

• Site Integration Testing (SIT) Coordination and Supervision

• Site Coordination from Initial Construction to Test and Commissioning

• Contractor/Owner Conflict Resolution and Mediation

• Inspection Services

• Client Representation Services

Cost estimating

• Feasibility/Preliminary

• Budgetary Analysis and Control

Regulatory and Permits

• Preparation of Permit Packages

• Submission of Permits

• Interfacing with Regulatory Bodies

Services Offered

IESL has been providing project management services for a number of operators such as, NNPC, SPDC, NAOC, etc.

Project Management Services Resources.

IESL has over 50 competent engineers in various disciplines working on site

Inspection Services

IESL specializes in the supply of a range of audit, inspection and supervision services for oilfield equipment within the onshore and offshore oil and gas industries. Services include:

• Onshore/Offshore rig and equipment

• Inspection, testing and condition reporting

• Equipment and instrumentation troubleshooting

• Well control equipment inspection services

• Development and implementation of onshore and offshore rig planned inspection and maintenance programs

• Audit services to monitor compliance with corporate and statutory requirements

• In-depth marine and safety surveys

• Development and audit of engineering and operating procedures

• Rig and equipment valuation services

• HAZOP, Safety Case, Risk Assessments, Trade-off Studies

• Equipment specific training

• Underwater Inspection

Rig Valuation Surveys

IESL conducts inspection and audit services as an independent, unbiased third party. Each audit is performed in accordance with ISO 9000 criteria and conducted to the highest professional standards. All audit data are treated as confidential and available only to auditee and client unless prior arrangement is made for the provision of equipment data to OEMs.

Formal written reports, together with supporting photographic records, are presented to clients upon completion of each audit or inspection.

Vendor Source Surveillance

Inspection services and computerized tracking for pipe and tubing to ANSI, ASME, ASTM and MI specifications. Our experience with double submerged arc welded, a seamless pipe and oil country tubular goods is of highest standard.

Painting & Coating Inspection

IESL provides quality control during application of anti-corrosion coatings for structural steel, pipe and other equipment. Inspection of corrosion protection can include OD/ID FBE, Tapes, Single Layer Extruded, Three Layer Extruded, Coal Tars, ID Flow Liners, OD/ID Concrete, Abrasion protection and other coatings.

Pipeline Construction Inspection

Process/project engineers and inspectors of all disciplines, including utility, environmental, right-of-way, trenching, welding and coating, can be provided in a team or individual for construction site work. This includes pipelines, civil structures and process plants.

Site Construction Inspection

Technical specialists of various disciplines perform visual, coating, NDE electrical and welding inspections at fabrication yards or offshore. Computerized traceability programs register all relevant documentation and results.

In-Service Inspection

Site inspection services from start-up through shutdown, designed to support maintenance, reliability and safety in various process industries.

Technical And Maintenance Services

The services offered by Technical Services division of IESL includes, but not limited to, the following:

- Rehabilitation and Repairs of Production Facilities

IESL provides rehabilitation or repair services including supply of materials, installations for pipelines, flowstations, platforms, compressor plants and valves.

• API tank Inspections and Process Safety Inspections

• Rehabilitation

• Degreassing and Deslugging

• Blasting and Painting

• Leak Detection and Repairs

- Pre-Commissioning Services

Newly constructed or refurbished pipelines are pre-commissioned to ensure that the pipe meets the requirements of the clients. IESL team of engineers offer pre-commissioning services in line with engineering standards.

- Pipeline Repairs and Fabrication

TSD offers the following repair methods which are acceptable in the industry.

• Composite Repair System

• Mechanical Bolt-in-Clamps

• Sectional Replacement

• Grinding

• Fully Welded Sleeves

• Weld Metal Deposit

We have certified welders and other technicians who carry out our welding jobs.

- Corrosion Analysis and Protection

IESL is fully aware of the devastating effect of corrosion and the attendant losses. It is therefore necessary to assess, analyze and proffer preventive measures as well as steps to be taken for the protection of corrosive equipment. IESL offers services to eliminate the causes of corrosion and also protect the equipment from decay by means of: Surface Treatments, Annealing, Cladding, Metalizing, Application of metallic paints, Coating of steel with other metals, Non metallic coating, Artificial building up of an oxide film or the production of a protective film of some other composition, and Cathodic Protection.

IESL with technical support of KnightHawk Engineering (KHE) of Houston, Texas, USA, our Technical Partner, has capability in Design, Failure Analysis, and Troubleshooting of Static and Rotating Equipment.

The technical approach also involves Service activities in Specialty Engineering such as: Finite Element Analysis, Computational Fluid Dynamics, Heat Exchanger Design, Piping Systems Analysis; and also in Field Services such as Data Acquisition (Flow, Pressure, Temperature, Vibration, Strain, Noise), Custom Instrumentation and Metrology- Digital Laser Scanning for modelling through Reverse Engineering for equipment that is obsolete or difficult to obtain from the OEM who may be giving too long to delivery time or totally out of production.

- Failure Analysis and Investigation

Our materials engineers and failure analysts provide independent expert opinions regarding materials failure analysis. Our analytical approach is to examine or test materials to evaluate the cause of your product failure. Our engineers can identify the root cause of your component failure. Features of material and metallurgical root cause failure analysis capabilities include:

• Analysis conducted by registered professional engineers

• Root cause failure analysis determination

• Photographic documentation

• Broad failure analysis experience

• Failure mode identification

• Fracture evaluations

- Failure Analysis Investigation

Failure of a component indicates it has become completely or partially unusable or has deteriorated to the point that it is undependable or unsafe for normal sustained service.

Typical Root Cause Failure Mechanisms

• Fatigue failures

• Corrosion failures

• Stress corrosion cracking

• Ductile and brittle fractures

• Hydrogen embrittlement

• Liquid metal embrittlement

• Creep and stress rupture

It is possible for fracture to be a result of multiple failure mechanisms or root causes. A failure analysis can provide the information to identify the appropriate root cause of the failure.

Solar And Power Engineering Services

Solar energy is an electric power generated from sunlight using devices called solar cell modules. It is also known as Photovoltaic (PV) Energy, which is a renewable energy technology that converts the sun’s light, not its heat, directly into electricity.

IESL offers the following services:

Design, Installation and Maintenance of Solar Energy Systems such as:

• Back-up System (UPS)

• Hybrid System

• Stand-Alone System (Off-Grid)

Design and Installation of solar powered:

• Communications:

Microwave transmitters and Receiver, Radio/Television Transmission and Reception, Ground

Station VSAT, Remote Telephones

• Rural Electrification: Home Lighting, Rural Electrification, Street and Area Lighting, Road Marking.

• Water Delivery: Portable Water Supply, Crop Irrigation

• Industrial Application: Construction Site Lighting, Cathodic Protection, Navigation Aids, Billboard Lighting.

Health Care

Solar energy is ideal for:

• Regional Hospital

• Rural Clinic

• Vaccine Refrigeration

• Mobile Clinic

• Dental Clinic

• Emergency Communication

Within the framework of power engineering services, we collaborate with reputable companies with hi-tech solutions in providing a range of services including power generation, transmission, line and distribution engineering and equipment such as power transformers, controls and sub-station installation and erection among others.

Rehabilitation design of existing power facility

• Circuit capacity upgrade and voltage

• Distribution line testing

• Inspection and evaluation of existing systems

• Complete sub-station design and construction

Consultancy services for:

• Contractor selection

• Bid evaluation

• Construction contract preparation, Inspection and Close-out

• Commissioning services

• Sub-station distribution protection and contingency analysis

• Load flows and short circuit

• Lighting protection and reliability improvement studies

• Power quality analysis and solutions

• System database revisions, studies, analysis, economic evaluation and development.

Quality, Health, Safety And Environmental services (QHSE)

Environmental Studies/Services

IESL capabilities for Environmental Studies/Services cover:

• Environmental Baseline Study (EBS)

• Environmental Impact Assessment (EIA)

• Environmental Audit/Monitoring (EA)

• Environmental Evaluation Report/Post Impact Assessment (EER/PIA)

• Environmental Site Assessment (ESA)

• Environmental Sensitivity Index Mapping (ESIM)

• Air Quality Studies and Gaseous Emission Monitoring

• Corrosion Control and Management

• Seabed Survey

Waste Management/Remediation/Environment Management

Waste Water Treatment & Offshore Chemicals

Solid Waste Management/Disposal

Hazardous Waste Management

Cleanup and Remediation of Oil Production

Sites Spills

Environmental Restoration

Oil Spill Contingency Planning

Waste Pit Construction/Management

Health, Safety and Environmental Management Systems (HSE-MS ISO 14001:2002/OHSAS 18001:1999)

We provide value-for-money HSE-MS Services to enable our clients:

• Achieve sustainable Health, Safety and Environmental compliance and maintain consistently high quality of HSE reporting and verification of good environmental management.

• Corporate reputation will be safeguarded and future liability claims from third-parties will be avoided or minimized.

IESL has the capability to carry out the following:

• Preparation of HSE-MS Manual, HSE plan and policies

• A review of existing HSE-Management System performance and recommend appropriate improvements.

• HSE-MS implementation, assisting the clients to go through the rudiments of HSE Management System.

Environmental Management System (EMS)

Improve and sustain your competitive edge by asking IESL to:

• Prepare or review the register of applicable Environmental Legislations for your organization;

• Review your procedures and format them in suitable formats which fully reflect EMS requirements applicable to your organization or business;

• Prepare and help implement EMS improvement Plan for your organization or business, based on an EMS

• Performance Review;

• Train your staff on Environmental Management System elements and carry out Environmental Awareness Workshops during training sessions;

• Carry out your outsourced process audits and inspections to international standards;

• Provide Environmental Management System Expert Manpower for your pressing Personnel needs.

Quality Management System (QMS)

IESL provides value-for-money Quality Management System Services to enable our clients achieve and sustain consistently high quality output of products and services, and deliver to customers’ satisfaction. The client’s Quality Management Systems are tailored to ensure the creation of top-notch products and services which remain market leaders.

IESL Quality Management System specialist will:

• Carry out a Preliminary System Evaluation: document review, external audits, assessment of system effectiveness, and recommendations based on initial findings;

• Help reduce operational costs by analyzing areas of waste and assist in improving overall effectiveness of your Quality Management System (QMS)-clear delivery of costs reduction as a consequence of setting up the Quality Management System;

• Help top train client’s Senior Management and Supervisors in QMS concepts and practices;

• Help to prevent a failed certification effort with attendant loss of morale and prestige;

• Help to reduce waste in process materials and operational costs using ‘Kaizen’ (ongoing improvement) approach;

• Offer assistance and guidance on selection of the appropriate target date for the certification audit by the external QMS assessment organization (ISO, SON);

• Provide Quality turn-around for ailing manufacturing and process industries;

• Prepare and implement a Quality Improvement Plan for your organization or business, based on a Quality Process Gap Analysis;

• Integrate existing HSE –MS with QMS to ensure consistency and avoidance of conflict with attendant waste (materials, documentation, energy, personnel skills, space, etc);

Health Management System (HMS)

Review and Upgrade your Health Management System

IESL will assist in reviewing your Health Policy and ensure that it is properly defined and functional.

IESL specialists will also help you to prepare your Health Standards and benchmark with other companies in similar areas.

IESL will help to keep up with legal health obligations to your staff and reporting compliance.

Health Management Skills and Competency Gap Analysis and corrective training can be arranged within your premises or outside as may be desired. Provision of First Aid training and First Aid Boxes by Employers are required by law.

IESL Health Management Specialists will:

• Provide Health Impact Assessment Studies (Health Risk Assessment, Health Impact Assessment, etc) where necessary o behalf of clients.

• Carry out a Preliminary Health Management System Evaluation: document review, external audits, assessment of system effectiveness, and recommendations based on initial findings;

• Carry out industrial Site Layout and Ergonomic Studies;

• Carry out Catering Hygiene Audits and Inspections, Kitchen Inspections, and

• Accommodation Hygiene Audits and Inspections;

• Provide Health Assessment Reports (HAR, HIA, etc) services for new and existing manufacturing and process industry companies. These reports – Health Impact Assessment (HIA) are required by the regulatory authorities and they may also improve a company’s corporate image while serving as defence in costly negligent injury litigation;

Procurement, Supply and After-sales Services of Safety, Health and Environmental Protection Equipment

IESL supplies the following items to the industry

• Anti-Slip Products

• Coveralls and other Work Clothing for various industrial personal protection needs, such as:

- Fire Resistance

- Fire Retardant

- Cotton

- Polyester

- Warm Clothing

- Eye & Face Protectors

- Chemical Goggles

- Impact Goggles

- Safety Glasses

- Specialized Safety Glasses (for personnel with eye defects)

- Face Shields

• Fire Extinguishers of various sizes for all classes of fire

• Fire & Gas Detectors

• Hand Gloves

• Hard Hats

• Safety Footwear

• Smoke Detector System

Laboratory Services

IESL material testing laboratory specializes in in-situ and laboratory data acquisition from soil, water and air. The services offered by the laboratory include:

• Hydrocarbon Analysis;

• Metals, Nutrients and Non-metals Analysis;

• Physical (pH, Conductivity, Alkalinity, etc) Characteristics Determination;

• Chemical, Biological and Microbiological Analysis;

• Petroleum Fingerprinting;

• Air Quality Measurement;

• Environmental Data Interpretation and Reporting

• Soil, Seawater and Sediment Sampling & Analysis;

• Water Analysis/Effluent Monitoring;

• Petroleum Geochemistry;

• BS µ W Determination.

Standards/guidelines being employed by our laboratory in analysis/measurement of soil, water and air among others include:

• American Society for Testing and Materials (ASTM);

• American Public Health Association (APHA);

• British Standard (BS);

• American Petroleum Institute (API);

• Environmental Guidelines and Standards for Petroleum Industries in Nigeria

• (EGASPIN);

• The World Health Organization (WHO).

Federal Ministry of Environment, Housing & Urban Development (FMEH&UD)

The quality objective of IESL Analytical Laboratory is to conduct sampling, testing and calibration services to internationally acceptable good practice.

Laboratory Equipment and Facilities

IESL is adequately equipped with modern laboratory equipments that are regularly calibrated and maintained. Some of the equipments in the facility are shown below:

Corporate Recruitment & Training

IESL is a proud participant in the Human Resources Development Programme of both the public and private sectors of the economy through its active involvement in corporate recruitment services, manpower development and training services.

Recruitment Services

Provision of all levels of technical specialists on contracts or project basis for the hi-tech and expertise dependent sectors Executive recruitment, selection and Placement for contract and permanent employment.

• Salary, compensation and incentives improvement planning

• Employee Job Performance Evaluation

• Employee Motivation and Mentoring

Training and Development Services

• Training Programmes

• Workshops

• Seminars & Management Retreat

• In-Plant Training of Professionals at all levels covering technical, non-technical and policy oriented programmes

• Collaboration with international training companies and institutions with excellent facilities.

Up-coming courses: These courses are also Available as in-plant.

• Corrosion Control in Tanks and Pipeline

• Fundamental of Oil/Gas Well Engineering

• Project Management

• An Introductory Course in Oil & Gas Industry operation

• Operation and Maintenance of Pumps, Valves & Actuators

• Operation and Maintenance of Gas Facilities

• Basic Workshop Practice

• Basic Petroleum Economics Course

• Advanced Petroleum Economics Course

• Supervisory and Managerial Development

• Skill Course for Engineers

• Energy and Facilities Management Course

• Management Skills for Secretaries and Personal Assistants

• Safety and General Management Courses

• Design Engineering Software Training

Quality System Accreditation

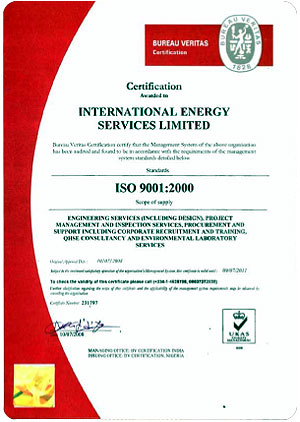

The quality of designs and project management services has always been a goal for IESL since 1990. IESL has operated a Quality Management System and this was certified ISO 9001 in July, 2008 by Bureau Veritas Certification.

ESL QMS is certified ISO 9001:2000 for:

• Engineering Design Services,

• Project Management Services,

• Inspection and Technical Services,

• Procurement,

• QHSE Consultancy and Environmental Laboratory Services

Quality Management System

The Quality Management System, under the Responsibility of IESL Quality Management Representative, is developed in the Quality Manual and comprises a full set of statements, instructions and procedures, applicable to any Work or services performed by IESL.

Office Locations

Iesl Head Office Is Located At:

Energy House,

94, Awolowo road,

Ikoyi, Lagos, Nigeria

OTHER OFFICES:

Plot 1661,

Oyin Jolayemi Street,

Victoria Island, Lagos, Nigeria

Suites 1 & 2 Jefia Estate,

PTI Road, Effurun,

Warri, Delta State, Nigeria

34 Old Aba

Road, Rumuomasi,

Port Harcourt, River State, Nigeria.

We can service many of our clients’ needs at very short notice. However, other offices are not only strategically located in active Oil and Gas producing areas, but are centres of excellence in their own right.

|