|

Cakasa (Nigeria) Company Limited

Developing full engineering, procurement, installation & construction capabilities

Overview

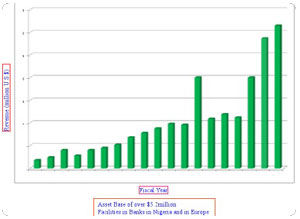

Cakasa (Nigeria) Company Limited was incorporated in 1974 to provide engineering, procurement, and construction (EPC) services to the Nigerian oil, gas, and industrial infrastructural clients. A trailblazer in the country’s oil and gas sector, Cakasa is one of the first indigenous companies to be ISO 9001:2000 certified.

Here in Cakasa, we use a flexible approach in building value that will meet the diverse needs of our clients. This approach provides a disciplined, client-focused framework that encourages and empowers management and employees to develop innovative solutions for complex challenges and to constantly improve our work environments and work processes. Our vast knowledge base, built on Cakasa’s over 33 years of EPC expertise, promotes collaboration and provides a systematic way to capture, share, and reuse the information to provide cost-effective, intelligent solutions in a timely manner.

In Nigeria, we have set a landmark for providing technical training for engineers and artisans, and our community relations strategies are purposefully focused to ensure a cordial and peaceful co-existence with the host communities in our areas of operation. We have the right team, the right experience, the right tools, the right approach and a proven track record for you to be assured that you will get the level of support you require.

Mission Statement

Cakasa is committed to being a leading Engineering, Procurement and Construction Company providing quality technical and management services through highly skilled and motivated employees. Total commitment to customer satisfaction, safety and excellent community relationship will be the basis for securing future growth and generating optimum returns for our stakeholders.

Our Partners

| Principal / Partner |

Service Type |

Type of Relationship |

| Fluor Corporation, USA |

EPCI and Maintenance Services |

Strategic Alliance |

| U.O.P. Inc, USA |

Commercialization of technology for license to Petrochemical industries |

Sole Representative |

| FMC Energy Systems, USA |

Measurement Solutions (Liquid, Gas & Integrated Systems) |

Exclusive Agent |

| ITT-Goulds Pumps, USA |

Industrial and Engineered Pumps fo

r all service applications |

Sole Representative |

| Tyco Valves & Control (Anderson Greenwood & Crosby Valves), UK |

Pressure Safety / Relief valves and instrumentation |

Distributor |

| Rotork Controls Ltd., UK |

Valve Actuators |

Exclusive Agent |

| Enraf Delf, Netherlands |

Tank Gauging System |

Distributor |

| HHI, Pump Division, Korea |

After Sales Pump services |

Exclusive Service Rep. |

| Sarens NV, Belgium |

Provision of Specialized Crane Services |

Alliance |

| Global Tech. Services, UAE |

IT Solution Providers |

Representative |

| Tapco International Inc. |

FCC Slide Valves |

Sole Representative |

Major Subcontractors / Vendors

| Subcontractor / Vendor |

Service Type |

| Vibroflotation & Geotechnical Services |

Soil improvement and geotechnical survey services |

| Nobaj Engineering Limited, Lagos |

Site investigation and piling foundation works |

| Akin Adisa & Associate |

Architecture & surveying services |

| Brownwoods Limited |

Architect and wood works |

| Testing & Inspection Services |

NDT & hydrotest, sandblasting and painting services |

| Techno-excell Services |

NDT & hydrotest, tank calibration services |

| Divcon Engineering Limited, Lagos |

Instrumentation and calibration services |

| Panat Nigeria Limited |

Shipment and custom clearing agent |

| Afritrade Limited, UK |

Freight forwarder, Europe and USA operations |

| Sari Sara, France |

Foreign procurement services |

| Toafad Nigeria Limited |

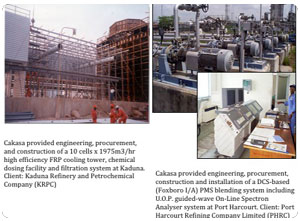

Local haulage services |

| Busitec Engineering Limited |

Electrical, power distribution and MCC panel services |

Nigerian Content

It is our intention to promote the Nigeria Content initiative of the Federal Government of Nigeria in optimizing the use of local resources and materials in the execution of our projects. Cakasa understands the need for sustainable development, and we are committed to the concept and the use of local resources. To this end, we shall continue to employ and train Nigerian citizens in all the disciplines that support the execution of our projects. We expect the mix of our personnel and those of our partners working together to produce a remarkable transfer of technology from our technical partners to Cakasa over the next few years as our personnel acquire the experience and skill to perform the work.

Engineering Office

Cakasa progressed into full scale engineering and project management services in 2002 following a strategic alliance with Fluor Corporation of USA. Fluor is a United States-based Fortune 500 company with over 100 years of experience and it is one of the world’s largest publicly owned engineering, procurement, construction, and maintenance services company. Our capabilities in engineering include:

- Feasibility studies / conceptual design

- Basic engineering design

- Front end engineering design

- Detail engineering design

- Drafting and as-built drawings including 3D

- Project management and engineering consultancy services

Most of our personnel have been involved in the execution of major projects with top international EPCM contractors such as Fluor, KBR, Bechtel, Technip, HHI, JGC, e.t.c and are therefore skilled in using the necessary engineering design software (see Software List below) tools to deliver projects that would meet international standard and to the satisfaction of our clients. Our target areas in the upstream and downstream sectors include but are not limited to:

- Offshore platforms

- Onshore and offshore pipelines

- FPSOs

- Marine terminals and oil/gas processing plants

- LPG / LNG plants

- Tank farms and loading facilities

- Refineries and petrochemical plants

- Power generation and transmission plants

- Utilities / Offsites, and other Civil/Mechanical Construction Works

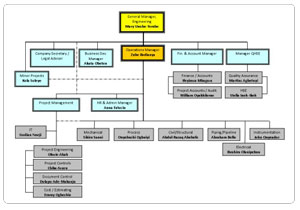

Office Location & Resources

Our engineering office is located in the business district of Falomo in lkoyi, Lagos, Nigeria. The proximity to our potential clients enables easy communication flow and quick response to client neds. We occupy a total office area of 1,229 m2 on three floors (1st floor – 394sqm, 2nd floor – 350sqm & 4th floor – 485sqm) at the Union Marble House Complex.

Our personnel mostly Nigerian (see table below), are skilled in their requisite fields to handle diverse tasks required to complete a project. Part of the gains of our strategic alliance with Fluor is the presence of Fluor experts (in our office in Ikoyi, Lagos) in the key engineering and project management disciplines to ensure effective transfer of technology. Our personnel are also deployed based on project requirements to Fluor engineering execution centers outside Nigeria to participate in the design of major projects and therefore acquaint themselves with Fluor work processes, design standards, systems, and practices. This exercise exposes the personnel to the international design environment as applicable to our target areas in the energy sector. Below is the average experience of our personnel in all the disciplines:

| S/N |

Position |

Qty |

Average Experience (Yrs) |

| 1 |

Management |

2 |

13 |

| 2 |

Lead Engineers |

6 |

11 |

| 3 |

Process Engineers |

12 |

6 |

| 4 |

HSE Engineers |

2 |

11 |

| 5 |

QA / QC Engineers |

3 |

10 |

| 6 |

Project Engineers |

5 |

5 |

| 7 |

Document Control |

3 |

5 |

| 8 |

Equipment - Mechanical Engineers |

11 |

6 |

| 9 |

Piping Engineers |

12 |

6 |

| 10 |

Pipeline Engineers |

6 |

4 |

| 11 |

Piping Draftsmen 3D |

5 |

5 |

| 12 |

Piping Draftsmen AutoCAD 2D |

7 |

6 |

| 13 |

Telecom Engineers |

2 |

4 |

| 14 |

Electrical Engineers |

12 |

6 |

| 15 |

Instrumentation Engineers |

10 |

5 |

| 16 |

Civil Engineers |

11 |

7 |

| 17 |

Structural Engineers |

8 |

6 |

| 18 |

Civil / Structural Draftsmen 3D |

4 |

5 |

| 19 |

Civil / Structural Draftsmen AutoCAD 2D |

8 |

6 |

| 20 |

Draftsmen – Process / Electrical / Instrument / Pipeline |

10 |

6 |

| 21 |

Procurement Support / Logistics |

3 |

10 |

| 22 |

Construction Support / Management |

3 |

12 |

| 23 |

Bus. Dev. / Project Control / Account / Admin. |

8 |

7 |

| Total |

153 |

|

Software

| S/N |

Software |

Use |

| 1 |

Aveva PDMS |

3D design and modeling |

| 2 |

AutoCAD 2004 |

Graphics design and drafting |

| 3 |

Hysis |

Process design and simulation |

| 4 |

Flarenet 2004 update 2 |

Flare design |

| 5 |

Pipesim 200.0.1 |

Hydraulic simulation and calculation |

| 6 |

Primavera Planner P6 |

Project planning and scheduling |

| 7 |

Microsoft Project 2003 |

Project planning and scheduling |

| 8 |

COADE (Tank) |

Design and analysis of storage tanks |

| 9 |

Caesar II V.4.50 |

Pipe stress analysis |

| 10 |

Auto Plant Group |

Design of pipelines and steel structures |

| 11 |

Instru Calc |

Major instrument calculations |

| 12 |

SKM Power Tools |

Integrated electrical analysis |

| 13 |

SACS Release 5.2 |

Structural analysis and design |

| 14 |

Smart Plant & Smart Sketch 4.0 |

Design of pipelines and steel structures |

| 15 |

Rebis CAE |

3D design, modeling and drafting |

| 16 |

InTools V.5.3 and Visio V |

Design and analysis of electrical, mechanical and instrumentation systems |

| 17 |

Microsoft Office Suite (Word, Excel, PowerPoint, Visio, Outlook, e.t.c) |

Normal office database documentation and calculations |

Training

Various programs are organized to develop personnel capabilities primarily in the areas of engineering and project management. This is designed to accommodate general courses for all and specific courses for engineers and designers. Specifically, the program is broken into three successive elements:

- An initial induction and familiarization program intended to provide a basic framework of competency, ensuring that all trainees receive an understanding of the working environment

- Detailed training programs combining discipline-specific training with a common element covering project execution issues, emphasizing the importance of teamwork

- An extended period of on-the-job (OJT) training

Past Experience in Engineering Design

Domestic Gas Supply Project – Mobil Producing Nigeria Unlimited

- This project originates from the FGN’s mandate to MPN to supply up to 100 MMscfd of natural gas to the Nigerian domestic gas market in 2009. The gas is to be specifically used for generation of electricity for domestic use

- The plan is to do a gas volume swap with SPDC and as such MPN will supply the required volumetric flow rate of gas via custody transfer metering to the SPDC GTS-2 pipeline feeding the NLNG plant at Bonny

- Scope of engineering includes the issuance of an IFC package that would ensure that the affected structural facilities and process systems are not compromised. MPN gas supply is to be sourced from the Nsimbo WA platform. There will be a tie-in from the discharge of the HP compressors, RG-K-105A/B on Oso RK to the Oso-BRT 12” fuel gas pipeline. Modifications to plant piping and new equipment are required to allow the Oso gas to be let down in pressure from approximately 5500 psig to 1400 psig and for downstream piping overpressure protection

- The Oso gas will then be directed through the existing 12” fuel gas line from Oso RX/RK/RG to Bonny River Terminal (BRT). At BRT the gas will be fiscally metered and then directed to both the SPDC 40” GTS-2 pipeline and Agip 36” GTS-4 pipelines. New equipment and modifications to plant piping are required at BRT to allow fiscal metering and for piping overpressure protection.

- Estimated engineering man-hours stood at 9,411.

Ubit GA & GC Slot Addition and Gas Lift Project – Mobil Producing Nigeria Unlimited

The scope of the Slot Addition project involves work required to add six (6) slots each on Ubit GA and Ubit GC. It also involves utilizing gas cap gas from a well to gas lift wells on the same platform. Activities include:

- Installation of 4” flow line from gas source well to gas lift manifold. Flowline will include an automated choke valve located at the gas source well casing wing valve to control the pressure in the gas lift manifold for Ubit GC

- Installation of a six (6) slot gas lift manifold (4” ANSI 900) with appropriate instrumentation (i.e. PSHH/PSLL) for Ubit GA

- Installation of 4” line to connect from boarding gas lift pipeline to gas lift manifold. Line to include pressure control valve and bypass for Ubit GA

- Installation of new gas lift flowlines (2” ANSI 900) with valves and instrumentation such as manually operated choke, corrosion inhibitor injection fittings, check valves, v-cone meter, flow recorder, pressure indicator, etc.

- Total man-hours for the project is estimated at 19,971.

Ubit As-Built Documentation Project – Mobil Producing Nigeria Unlimited

- The project scope was to prepare a complete as-built documentation of the Ubit field facilities whether previously inaccurate, incorrect or non-existent

- The as-built documentation involves the laser scanning, documentation and quality assurance checking of the as-built drawings of 13 Ubit platforms and 4 Unam platforms

- This includes detailed data acquisition of systems, structures and ancillary equipment using 3D scanning to capture dimensional information of existing facilities which would be used to create 2D drawing deliverables

- 13, 489 man-hours was spent on the project

Ubit GD & GF Gas Lift Project – Mobil Producing Nigeria Unlimited

- Ubit GD & GF are remote wellhead platforms located approx 1km and 2.6km from the production platform, Ubit GP

- The project is targeted at gas lifting 5 wells each on Ubit GD & GF wellhead platforms

- The gas source wells for Ubit GD & GF will be existing oil producers (wells 72D and 67F) recompleted into the gas cap

- A total of 9,871 man-hours was spent

Etim LP / Inim IP Restoration Project – Mobil Producing Nigeria Unlimited

- Scope was to restore two production platforms Etim LP and Inim IP to full production from their current shutdown state within the shortest possible time

- This would be done via the demolition and replacement of diverse piping, valves and instrumentation with minor structural works on both platforms

- Man-hours expended on this project totals 1,733

Oso RC, RR & RP As-Built Documentation Project – Mobil Producing Nigeria Unlimited

- The project covers the As-Built Documentation of Oso RR, RP & RC platforms under the Oso Production Asset

- Detailed scope includes the Laser Scanning, Drafting, QA/QC and Field Verification activities to be executed under the project as well as the preparation and Issue of Final “AS-BUILT” drawings, datasheets and reports including all other requirements

- This project is due to be completed December this year and a total of 8,828 man-hours is expected to be utilized

Usan FPSO FEED Project – Total E & P Nigeria Limited

- Doris Engineering worked with DeltaAfrik, Cakasa and Crestville on this project

- The FEED scope includes the FPSO, SPS, UFR and the export lines to a loading buoy

- The project was executed from both the Doris Office in Paris, France and the DeltaAfrik Office in Lagos, Nigeria

- 8 of our engineers from process, mechanical, piping, instrumentation and structures were seconded to both offices and 11,682 man-hours were expended

East Area Project – Mobil Producing Nigeria Unlimited

- The detailed engineering took place in HHI office in Houston, then the team moved to Ulsan, Korea for follow-on engineering and fabrication support

- Our scope was to produce structural drawings (IFA to IFC), SACS analysis, PDMS modeling and structural designs

- Additional scope included mechanical reviews of the electrical, instrumentation and piping of the flare bridge

- 6 of our engineers worked on this project and a total of 19,064 man-hours was utilized

Gbaran-Ubie New Manifolds Project – Shell Petroleum Development Company of Nigeria Limited

- Daewoo subcontracted the detailed engineering to Fluor who worked with Cakasa

- The project objective is for Shell to meet its commitment to supply gas to the NLNG facilities and also to increase oil production

- Our scope ranges from process, piping, electrical, control systems and civil/structural analysis of the gas facilities

- 8 of our engineers were involved in this project and a total of 11,360 man-hours was spent

Akam and Ebughu PP. Engine & Generator Change-out of two Existing and replace with two new on both Platforms – Addax Petroleum Development Nigeria Limited

- Scope of services includes the design of a synchronizing system for a new 415V, 3PH&N, 50Hz switchboard

- The switchboard is to be powered by 2 nos 500 KVA, 415V, 50Hz generators and 1 nos 100 KVA, 415V, 50 Hz emergency generator

- The 2 main generators are to run as Running / Standby hence to have auto and manual synchronization, stand alone panels, and are to be gas started (no batteries). The emergency generator is also to be battery started.

- 3,273 man-hours was expended on the project

Alaoji Gas Supply Pipeline Project – NGC / Taba Nigeria Limited

- The client is Nigeria Gas Company while Taba Nigeria Limited is the EPC contractor

- The project is the FEED, detailed engineering and project management services of a 24” x 21km pipeline from source of hot tapping to a metering station and a 18” x 4km pipeline from the metering station to the gas plant all in Alaoji, Imo State, Nigeria

- A total of 16,947 man-hours was spent on the project

As-Built P&ID Documentation for Izombe & Issu Fields – Addax Petroleum Development Nigeria Limited

- Scope includes updating the facilities P&ID drawings including equipment tags and identification numbers

- We are also required to update existing drawings and produce new ones when necessary to truly reflect facility installations on site

- 2,190 man-hours was expended

Agbami FPSO Project – Chevron Nigeria Limited

- Daewoo subcontracted the detailed engineering of the Agbami FPSO topsides to KBR

- KBR executed the project with the consortium of NETCO, Cakasa and other indigenous engineering firms

- 9 of our engineers worked with KBR and NETCO teams both in Houston and here in Lagos

- A total of 7,410 man-hours was expended on this project by our engineers

Detailed Engineering Design for EGP-3A Project – Chevron Nigeria Limited

- HHI subcontracted the design and drawing of jackets, piles and tripod of the detailed engineering to Cakasa

- The project was executed in Lagos and total man-hours expended was 6,720

Escravos Gas to Liquid Project – Chevron Nigeria Limited

- KBR handled the detailed engineering

- Our personnel were seconded to their Houston office to handle instrumentation and control design scopes

Nsiko Field Study – Chevron Nigeria Limited

- Global Petroleum Resources Limited did the field study with 7 of our engineers on secondment to render process, electrical, mechanical/piping and instrumentation design services

H-Block Development Project – Shell Petroleum Development Company

- FEED Project was handled by NETCO

- 2 of our engineers were seconded on this project to carry out HSE and mechanical design

Bonga Northwest Project – SNEPCO

- FEED project was handled by NETCO

- 2 of our engineers worked in that team on electrical & instrumentation

Temporary Rental of Power Generators (10MW) & Related Services for Lafarge Wapco Cement Ewekoro Plant – Lafarge Wapco Cement Nigeria Plc

- This is an Independent Power Plant (IPP) Project to be located at Lafarge Wapco Ewekoro Cement Plant Nigeria

- The EPC contract was awarded to Shoreline Power Company Limited while Cakasa provided engineering design works and project management

- Cakasa’s scope of work includes:

- Review of Load Profile Calculations

- Review and finalization of Single Line Diagram

- Integration of individual supplier drawings into complete plant drawing

- Verification of individual supplier drawings in terms of technical integration into complete system drawings

- Verification and approval of site works by suppliers before final testing and commissioning of plant

- Layout review in terms of safety requirements

- Calculation of Exhaust pipe heights

- Additional firefighting equipment required (Note: Main fire fighting provided by client on site)

- Gas reduction station and gas pipeline work

- Foundation base details for Containerized Switchgear, Transformers / Gas turbine, Control Room, Service container etc

Procurement

Cakasa (Nigeria) Company Limited maintains a strong relationship with reputable manufacturers overseas whose products are used in the oil & gas and process industries here in Nigeria. We have an agreement with these manufacturers to locate market for their products, and also provide after sales services to the beneficial clients. Manufacturers with which we have such agreements include: FMC Measurement Solutions, Anderson Greenwood Crosby, UOP, ITT Goulds Pumps, e.t.c (see “Our Partners” above), and some of their products are listed below:

- FMC Liquid Equipment – Flow (PD, turbine, mass) meters & computers, pipeline products, e.t.c

- FMC Gas Equipment – Gas flow (orifice fittings, multiphase, ultrasonic) meters & electronics

- FMC Systems – Metering (gas & liquid) systems, LACT, prover, supervisory control, e.t.c

- Enraf – Automatic tank gauging instruments and inventory management systems

- Rotork – Motorized electric & fluid powered actuators and control systems

- Pepperl + Fuchs – Factory (sensors) Automation and Process (control systems) Automation

- Tapco – Refineries’ FCCU slide / flapper / plug / bolt-less valves and actuators

- Tyco – Pressure safety / control / isolation valves, actuators and instrumentation

- ITT Goulds Pumps – Process / stock / fan pumps and systems

- UOP molecular sieves – Refining, petrochemical, gas processing, absorbents, equipment & systems.

- Anderson Greenwood Crosby – pressure safety valves and pressure relief valves

- Flowserve/Valtec – pressure control valves and level control valves

- Black Clawson – palletizing systems

- US Filter/Zimpro – high pressure hydraulic pump spares

- Neu Transf’ Air – classifier screen and heat exchanger tube bundles

- Farvra International - cooling tower spares

- Spirax Sarco – steam traps and process fluid control

- Ionic Italba – waste water/water treatment

Apart from the above, we also engage in high volume procurement and supply of line pipes, subsea cables, and other materials as our clients may require from time to time. We are quite familiar with a majority of the oil and gas facilities in the Niger delta region having been supplying equipments and spares for the smooth running of these plants before now and so we are in the appropriate position to verify the technical accuracy of your equipment specifications to ensure that the right order is made the first time. We also render after sales and operational maintenance services.

In order to ensure that quality products / materials are delivered first time and every time, manufacturing shall only commence after Client‘s approval in cases of major equipment supply or modification. Our appointed independent inspectors would undertake process inspection of the materials at different stages of the manufacturing process. We take responsibility for the shipping and delivery of all products / materials to site, and we establish and maintain proper co-ordination and communications with Client with regard to any difficulties with import and customs documentation requirements.

We have over 34 years of experience in shipping, importation and custom clearance in Nigeria and therefore well acquainted with the in-country import regulations particularly with respect to pre-shipment inspection in Country of Origin by a Nigerian Customs Representative and the current 100% destination inspection being performed by the Nigerian Customs Service at the ports. All products / materials are insured ex-factory to delivery to site and the client is liable for this service.

Construction

LPG Facility

In 2007, Cakasa (Nigeria) Company Limited commenced operation in the design and construction of LPG storage facilities with the award of the contract to build two, 8000 tons LPG spheres for NAVGAS in Apapa Lagos. This contract was executed in partnership with TISSOT, France and SIRAGA Belgium to develop local capabilities in the building of LPG facilities here in Nigeria.

Civil Construction

We are an industry leader in the field of civil construction. We have the expertise to construct heavy equipment parking platforms, jetties, high rise buildings, pavements, e.t.c. Cakasa built the first modern petroleum tankers parking lot at Iganmu, Lagos, Safety Centre International in Port Harcourt, Power Holding Company of Nigeria’s Control Centre complete with helideck and other infrastructural facilities in Benin, Edo State, Nigeria and various private residential buildings in different locations in the Lagos metropolis. Presently, we are in the verge of completing the multimillion naira parish complex for St. Leo’s Catholic Church, Toyin Street, Ikeja, Lagos.

Upstream & Downstream Construction Capabilities

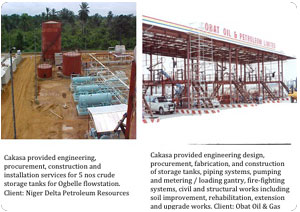

Cakasa is a leader in both upstream and downstream construction activities. From the successful completion of the Ogbainbiri flowstation upgrade owned by NAOC in 2004, Cakasa has been in the design and construction of oil and gas facility vessels and tanks such as surge tanks, produced water, crude tanks, diesel tanks, e.t.c. We also design and construct arrival manifolds for gas gathering systems, installation of packaged equipments on flow stations, e.t.c. Presently, we are executing an engineering, procurement and construction contract for the addition of new arrival manifold extension for eight (8) flowlines for the Obrikom/Obiaku Gas Plant (owned by NAOC) in Omoku, Rivers State.

In the downstream sector, our areas of expertise includes: Turnkey design and construction of tank farms for the receipt, storage, and offloading of petroleum products. We have successfully carried out EPC contracts for green field tank farms such as Obat Oil Lagos, Lister Oil Lagos, Northwest Oil Calabar, Sahara Energy Lagos, amongst so many others.

Our capability in this area includes both fixed and floating roof storage tanks, design and construction of the interconnection pipeline network, installation of equipments (such as pumps, compressors, generators), design and construction of loading gantries for both top and bottom truck loading, tank farm integration systems, product receipt and metering system, tank farm electrical power, control, earthing and lighting protection systems, all civil works (including tank foundations, bond walls, drainages, oil water separators), site landscaping works, tank farm security systems, e.t.c.

Upgrade of Existing Tank Farms

We also undertake the upgrade of existing tank farms. We redesign and reconstruct tank farms to meet present stringent standards in the oil and gas industry. We successfully carried out an upgrade of PPMC/NNPC depots between 2002 and 2003, Total/AP Aviation Terminal in Abuja, Nigeria, Heyden Petroleum Ijora, Lagos, among others.

Cakasa also specialize in the refurbishment of storage tanks. We have specialized equipment to jack up tanks for foundation and tank base repairs, replacement of corroded tank shells, increasing the tank capacity by adding more shells to existing tanks, conversion of fixed roof storage tanks to floating roof tanks, and upgrade of tank safety systems. We have upgraded storage tanks for Total tank farm Apapa, Zenon Tanks, Ibafon, Heyden Petroleum Ijora, e.t.c.

Pipelines and Terminals

We provide engineering, procurement, construction, construction management, and maintenance services for onshore and offshore pipelines and terminals. Cakasa’s domestic experience in this regard and our partners international experience gives us the required edge over our competitors in delivering cost-effective solutions that minimize capital and operating expenditures.

Of particular relevance is our understanding of these projects – from first principle and detail design through their operations and maintenance – enables us to approach the critical preliminary design of pipelines and terminals with the mentality of optimizing value, operability, and reliability. The success of any pipeline and terminal project is measured in terms of quality, safety, time, and capital involvement both during the design, construction and operation. Below are some of the pipelines projects we have executed in the past:

| Year |

Client |

Location |

Length |

Diameter |

Project Description |

Scope |

Value (US$) |

| 2008 |

Taba / NGC |

Lagos |

25km |

24”, 18” |

Alaoji gas supply pipeline project |

FEED, E |

760,000 |

| 2008 |

Port Harcourt Refining Company |

Okrika Jetty |

300m |

18”, 16”, 10”, 8”, 6” |

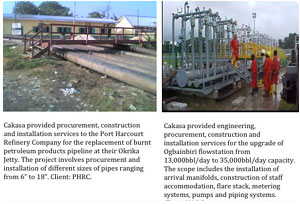

Replacement of Burnt Pipelines |

P, C |

470,086 |

| 2007 |

Northwest Petroleum Nigeria Ltd. |

Calabar |

1.5km |

8” |

Design and construction of connecting pipeline from common header to depot receiving point. |

E, P, C |

765,218 |

| 2006 |

Ibafon Oil Nigeria Ltd. |

Calabar |

1.2km |

8”, 6” |

Design and construction of a common header product pipeline |

E, P, C |

820,513 |

Where: E – Engineering; P – Procurement; C – Construction; FEED – Front End Engineering Design

Workshops / Warehouses / Fabrication Yards

Workshop facility in Port Harcourt – This facility is easily accessed from the main road with over 9,500 m2 of space available for fabrication, construction and maintenance services. It also contains an office space of over 600 m2 and a mobile workshop for PSV certification and maintenance. The Port Harcourt facility also house a machine shop with lathe machines, milling machines, shaping machines, cutting machines and fabrication equipment for mechanical seal refurbishment and machining works.

Workshop facility in Warri – Situated along the NPA Expressway, this facility is easily accessed by land or sea. It has over 1,500 m2 of space available for fabrication and construction, and about 500 m2 of office space including a canteen and clinic with adequate parking spaces for vehicles.

Others are fabrication yards at Ikeja, Concrete batching yard at Okota, Warehouse at Onipetesi, Ikeja, Lagos, e.t.c. All yards / workshops have storage spaces for short and long term storage and they are well equipped with plant and equipment which includes but not limited to welding machines, compressors, generating sets, lifting equipment including 4 sets of tank erection jacks, cranes, bulldozers, levelers, fork lifts, plate rollers, cutting machines, concrete mixers, dumpers, vibrators, pumps, leveling instruments / theodolites, e.t.c.

Project Management

We manage the competing demands of scope, cost, quality, safety and schedule to deliver world-class program and/or project management services to our global clients. Cakasa's engineers continue an almost 6-year-old tradition of developing world-class, capital projects in a variety of industries around the country. The individual and collective project and technical expertise of our personnel gives us the required edge to enable us deliver appropriate, cost-effective solutions to our clients in order to maximize their assets, improve their competitive position, and increase their long-term business success.

The conceptual design phase of any project offers the best opportunity to assess business, commercial, and technical risk and improve return on investment. During conceptual design, Cakasa establishes the “early project” definition of the engineering, procurement, and construction requirements and a detailed project estimate. The early project services include feasibility studies, project development planning, technology evaluation and recommendations, risk management assessment, global siting, financing planning, constructability reviews, asset optimization over the facility's life cycle, and front end engineering. Clients rely on the comprehensive experience of our experts to plan successful projects.

Project Controls & Progress Measurement

Planning, scheduling, progress, and performance measurement are the responsibility of our Project Controls Manager. Scheduling and progress control dynamically interrelate with estimating and cost control, and the two function as one in coordinating with other groups on the project team. Cakasa project controls team will provide Client a vital framework for managing and controlling the scope, schedule, and cost of each project executed by our team. The control team focuses clearly on the unique contractual requirements of the project, and will consistently achieve predictable results with assurance of excellence and without surprises for the Client.

Our project control team also measures actual project data against the control base at regular intervals. The categories that are measured typically include the engineering progress at the office and the construction progress on-site, along with the performance at both sites, giving special attention to the completion of critical path activities. Status reports are used to document and control the critical aspects of project execution.

Project Information Management

Our project information management team comprised of experienced professionals working closely with partners and clients in achieving seamless flow of information during the entire lifecycle of your project. Some of the equipment already in place to achieve this includes:

- A 2mbps SCPC dedicated VSAT connection. The system links our offices nationwide and permits data exchange with our clients and partners around the world.

- A HP Proliant ML350 (Server), Compaq Evo DX6100 PIV 3.0 GHZ Processors, 80GB HDD, 17” Monitor 40/80 internal DDT Tape Drive.

QHSE Management System

Quality Policy

We shall continuously deliver services that meet customer needs and expectations as a demonstration of our total commitment to customer satisfaction.

Quality System

Cakasa’s Environmental Management System (EMS) meets the requirements of the voluntary International Standard Organization’s ISO 9001 by addressing the Health, Safety and Environmental (HSE) design, development, production, installation and servicing of client projects. Cakasa maintains ISO 9001 certification in all our offices nationwide. Our ISO 9001 quality systems and procedures take account of relevant guidance provided in ISO 9001: 2000, and it forms the basis for quality system management and control in all the projects we execute.

Cakasa HSE Practices / Procedures and Forms are updated from time to time to meet changes in requirements world-wide. Cakasa will maintain quality control in its HSE regimen by utilizing the ISO 9001 elements to measure environmental management requirements. This is an ongoing effort, tracked by the HSE Manager with Cakasa Practices and Procedures. Record of Accountability is part of the hand-over reports usually provided to Client during initial operations transfer from Cakasa to Client management.

Quality Assurance & Control

To ensure that our projects meets the needs of the client and international standards, we in Cakasa have designed a quality program that will implement the following specific activities to provide objective evidence that the projects we undertake conforms to the specified project requirements:

- An internal verification system consisting of formal, structured checking regime to assure the integrity of products (deliverables) by the originating discipline, squad-checking of products (deliverables) by other groups and specialist functions, having a relation with the subject as defined in the departmental interface procedures and the Activity Plans, e.t.c

- Auditing, surveillance, and inspection by Quality Assurance/Quality Control (QA/QC) personnel, with authority to assist the Project Team in the development of the Project Quality Plan, perform Quality Assurance reviews of documents, e.t.c, and

- Third-Party quality audits by Cakasa’s ISO 9001 Certification Body. Third-party audits by the Certification Body are conducted on a yearly basis.

Health, Safety & Environment

Successfully managing HSE issues is an essential component of our business strategy. Through observance and encouragement of our HSE Policy and Program, we assist in protecting the environment and the overall well-being of all of our stakeholders, specifically, our employees, clients, subcontractors, and host communities. Our goal is to minimize impact to the environment and to prevent harm to all who could be affected by our operations.

We are committed to reducing waste, emissions, and discharges in all areas where we work and by using energy efficiently, we strive to be good citizens in every community in which we operate. Cakasa will maintain awareness of HSE issues, so as to be proactive in providing a value-added service to our clients. This awareness is achieved through education, communication, and definition of the goals and standards appropriate to our operations and those undertaken on behalf of our clients. In this regard, we will adhere to our principles which are the cornerstone of Cakasa’s health, safety and environment culture and address issues such as accountability, training, communication, resources, engineering design, performance measurement, and sustainable development. Cakasa has established and is committed to a Zero Incidents goal.

Office Security

Cakasa’s standard office security measures form the basis of any project’s office security plan. One of such security measures includes the installation of additional card readers to limit access to the project area to only project personnel. Additionally, access is limited to certain locked files (key control) and access to project files on the fileserver is also limited to the required project personnel. This is to ensure that only authorized persons have access to project / client information while unwanted client documents are shredded via shredders available in the office.

Cakasa Corporate Experience Summary

| S/N |

Client / Location |

Project |

Scope |

Value (US$) |

Year |

| 1 |

ExxonMobil, Lagos |

Domestic Gas Supply Project |

E |

495,761 |

2009 |

| 2 |

BPS, SA, Cotonou |

Design and Construction of Cotonou Depot |

EPC |

14,069,724 |

2009 |

| 3 |

ExxonMobil, Lagos |

Ubit GA & GC Slot Addition & Gas Lift Project |

E |

880,587 |

2009 |

| 4 |

St. Leo Catholic Church, Lagos |

Design and Construction of new Parish Complex |

EPC |

3,002,772 |

2009 |

| 5 |

ExxonMobil, Lagos |

Oso RC, RR & RP As-Built Documentation Project |

E |

1,508,359 |

2008 |

| 6 |

ExxonMobil, Lagos |

Etim LP & Inim IP Restoration Project |

E |

462,415 |

2008 |

| 7 |

ExxonMobil, Lagos |

Ubit Field Wide As-Built Documentation Project |

E |

2,417,331 |

2008 |

| 8 |

ExxonMobil, Lagos |

Ubit GD & GF Gas Lift Project |

E |

499,570 |

2008 |

| 9 |

Lafarge Wapco Cement, Ewekoro, Ogun State |

Temporary Rental of Power Generators & Related Services (10MW) – Ewekoro Plant |

E |

132,051 |

2008 |

| 10 |

Addax Petroleum, Lagos |

Akam and Ebughu PP. Engine & Generator Change-out of two Existing and replace with two new on both Platforms |

E |

342,200 |

2008 |

| 11 |

Chase Petroleum, Ghana |

Engineering Design of Petroleum Products Storage & Loading Facilities |

E |

200,000 |

2008 |

| 12 |

First Deepwater Petroleum, Lagos |

Engineering Design of Petroleum Products Storage and Loading Facilities |

E |

196,581 |

2008 |

| 13 |

Samon Petroleum Limited, Lagos |

Engineering Design of Petroleum Products Storage and Loading Facilities |

E |

128,205 |

2008 |

| 14 |

ExxonMobil / HHI, Lagos |

East Area Project Detailed Engineering |

E |

629,110 |

2008 |

| 15 |

Castlatel Petroleum Limited, Lagos |

Engineering Design of Petroleum Products Storage and Loading Facilities |

E |

200,855 |

2008 |

| 16 |

Integrated Oil & Gas Limited, Lagos |

Engineering Design of Petroleum Products Storage and Loading Facilities |

E |

85,470 |

2008 |

| 17 |

Total, Lagos |

Abuja Aviation Depot Rehabilitation |

EPC |

1,000,000 |

2008 |

| 18 |

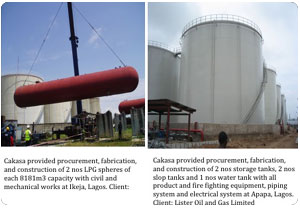

NAVGAS, Lagos |

Construction of 2 nos LPG Spheres of 8181m3 capacity each |

PIC |

5,200,000 |

2008 |

| 19 |

St. Leo’s Catholic Church, Lagos |

Design and Construction of Parish Complex |

EPC |

3,028,436 |

2008 |

| 20 |

PHRC, Port Harcourt |

Replacement of Burnt Pipelines at Okrika Jetty |

EPC |

378,376 |

2008 |

| 21 |

SPDC, Port Harcourt |

Export Metering Systems Maintenance |

PM |

250,000 / yr |

2008 |

| 22 |

NLNG, Bonny |

5 year Call-Off Contract for Molsieve Changeout |

M |

600,000 / yr |

2008 |

| 23 |

TSL / Oando Plc, Lagos |

PHC Terminal Upgrade |

EPC |

6,900,000 |

2008 |

| 24 |

Various Operators |

Valves Servicing, Maintenance, Calibration |

PM |

1,500,000 / yr |

2008 |

| 25 |

Addax Petroleum, Lagos |

As-Built P&ID Documentation for Izombe & Ossu Fields |

E |

215,300 |

2007 |

| 26 |

SPDC / Fluor |

Gbaran Ubie Integrated Project Detailed Engineering |

E |

1,012,960 |

2007 |

| 27 |

PHCN, Benin |

Design and Construction of Regional Control Centre & Facilities |

EPC |

1,500,000 |

2007 |

| 28 |

Northwest Petroleum, Lagos |

32 ML Storage Tank Farm complete with 6 Bay loading facilities at Calabar Free Trade Zone |

EPIC |

8,000,000 |

2007 |

| 29 |

Sahara, Lagos |

Ghana Petroleum Products Storage Facilities |

Ct |

50,000 |

2007 |

| 30 |

Total, Lagos |

Petroleum Products Tank Construction (3 yrs) |

EPIC |

1,500,000 |

2007 |

| 31 |

Lister Oil, Lagos |

Petroleum Loading Depot – Storage Tanks, Loading Facilities & Piping |

EPIC |

2,000,000 |

2007 |

| 32 |

Platform Petroleum, Lagos |

Engineering and Construction of 2 nos x 10,000bbls Crude Tank plus 1 nos Fire Water Tank |

EPIC |

600,000 |

2007 |

| 33 |

AMEC Engineering, Lagos |

Design & Construction of 8 Hectares of Pavement for Oil Tanker Terminal at Iganmu-Orile, Lagos |

EPC |

6,500,000 |

2007 |

| 34 |

Chevron / HHI, Lagos |

Escravos Gas Project (EGP-3A) Detailed Engineering |

E |

225,600 |

2006 |

| 35 |

Chevron / KBR, Lagos |

Agbami FPSO Detailed Engineering |

E |

250,000 |

2006 |

| 36 |

SNEPCO / NETCO, Lagos |

FEED for Bonga Northwest Project |

E |

248,300 |

2006 |

| 37 |

CFTZ, Calabar |

Bulk Liquid Storage Facilities Pipeline Project |

E |

820,513 |

2006 |

| 38 |

NDDC, Port Harcourt |

Ogba – Benin Water Project |

EPIC |

1,000,000 |

2006 |

| 39 |

NAOC, Port Harcourt |

Global Maintenance of Metering Facilities (3 yrs) |

PM |

6,000,000 |

2006 |

| 40 |

Fed. Min. of Works, Abuja |

Rehabilitation of Ife-Ondo Road (Total of 60.4km) |

PC |

16,295,000 |

2006 |

| 41 |

Fed. Min. of Internal Affairs, Abuja |

Supply of 4 nos x 500kva Gen Set & 4 nos x 500kva Transformer to PHC, Enugu, Kano & Lagos Prisons |

PI |

615,000 |

2006 |

| 42 |

SPDC, Warri |

FT Bidirectional Prover Loop Replacement (FMC System) |

PIM |

350,000 |

2006 |

| 43 |

Total E & P, Lagos |

Usan FPSO FEED Project |

E |

595,780 |

2005 |

| 44 |

Mobil, Lagos |

Automated Lube Oil Blending Plant |

IC |

1,350,000 |

2005 |

| 45 |

NPDC, Benin |

2-meter run Crude Oil Metering Skids |

EPC |

150,000 |

2005 |

| 46 |

Sahara, Lagos |

29 Million Litre Storage Tanks Construction |

EPC |

2,400,000 |

2005 |

| 47 |

SPDC, Warri |

Upgrade of Terminal Metering Facilities |

EPC |

1,500,000 |

2005 |

| 48 |

SPDC, Port Harcourt |

Supply Agreements (Smith & Tyco Products) |

PIC |

4,500,000 |

2005 |

| 49 |

Romi Oil, Lagos |

Petroleum Products Depot & Lube Plant |

Ct |

50,000 |

2005 |

| 50 |

Global Fleet, Lagos |

Mega Service Station Construction |

EPIC |

250,000 |

2005 |

| 51 |

SNEPCO, Lagos |

EA Gas Lift and Flowline Upgrade |

PIC |

1,000,000 |

2005 |

| 52 |

Chevron, Lagos |

Escravos Gas Plant – Molsieve Changeout |

M |

400,000 |

2005 |

| 53 |

MPN, Lagos |

Oso RX – Molsieve Supply and Changeout |

PM |

1,400,000 |

2005 |

| 54 |

NAOC, Port Harcourt |

Ogbainbiri Flowstation Facilities Upgrade |

EPIC |

6,000,000 |

2004 |

| 55 |

Obat Petroleum, Lagos |

Petroleum Products Loading Facility |

EPIC |

10,000,000 |

2004 |

| 56 |

NAOC, Port Harcourt |

70,000bpd Crude Oil Metering System |

PIC |

650,000 |

2004 |

| 57 |

NPDR, Port Harcourt |

Ogbelle Flowstation Crude Oil Storage Tanks (5 nos) |

EPIC |

842,274 |

2004 |

| 58 |

Zenon, Lagos |

Soil Treatment and Civil Foundations for Storage Tanks (3 nos) |

EPIC |

1,330,000 |

2004 |

| 59 |

PPMC, Abuja |

Depot Rehabilitation and Terminal Automation – Kano, Mosimi, Ejigbo, Ibadan, Benin |

EPC |

2,600,000 |

2003 |

| 60 |

NAOC, Port Harcourt |

Construction of Oshie Fire Water Tanks |

EPC |

300,000 |

2003 |

| 61 |

SPDC, Warri |

Egwa WIP Instrumentation Revamp |

PCM |

100,000 |

2003 |

| 62 |

Carlson Bermuda, Port Harcourt |

Evaluation of LPG Facilities at PHRC & Okrika Jetty |

EPC |

233,766 |

2003 |

| 63 |

SCI, Port Harcourt |

Build and Equip Safety Centre |

EPC |

2,136,752 |

2003 |

| 64 |

PHRC |

Refurbishment of the old Truck Loading Facility (Area 5) – Offsite Improvement Project |

PIC |

59,618 |

2003 |

| 65 |

Petrostar Nigeria, Port Harcourt |

Supply, Installation and Commissioning of Loading Gantry Equipment, Pumps and Fire Fighting System |

PIC |

1,100,000 |

2003 |

| 66 |

SPDC, Port Harcourt |

Maintenance of Centrifugal Pumps |

PM |

100,000 |

2003 |

| 67 |

SPDC, Warri |

Rehabilitation of XXHP Test Separator |

PCM |

100,000 |

2003 |

| 68 |

SPDC, Warri |

Manifold Extension & Flowlines Hook-up |

EPC |

500,000 |

2003 |

| 69 |

DBN / KRPC, Kaduna |

TAM Support Services (PSVs & CVs Certification) |

PM |

100,000 |

2002 |

| 70 |

PPMC, Kaduna |

Depot Rehabilitation and Terminal Automation |

EPC |

1,100,000 |

2002 |

| 71 |

PHRC, Port Harcourt |

PMS Blending System (DCS Controlled) |

EPC |

1,200,000 |

2002 |

| 72 |

DBN / WRPC, Warri |

Turn Around Maintenance Support Services |

PM |

1,330,000 |

2002 |

| 73 |

SPDC, Warri |

Overhaul of Terminal Metering Facilities |

PC |

500,000 |

2002 |

| 74 |

WRPC, Warri |

Rehabilitation of the Earthing System at NNPC Truck Loading Bays |

PIC |

141,892 |

2002 |

| 75 |

Sahara, Lagos |

Engineering Services for Ibafon Storage Tanks Facilities |

Ct |

60,000 |

2001 |

| 76 |

KRPC, Kaduna |

Rehabilitation of Cooling Towers |

PC |

7,000,000 |

2001 |

| 77 |

KRPC, Kaduna |

Replacement of Faulty System Traps |

PC |

1,860,000 |

2001 |

| 78 |

KRPC, Kaduna |

Rehabilitation of Chemical Dosing Facility |

PC |

500,000 |

2001 |

| 79 |

Texaco, Lagos |

6 Bay Refined Products Loading Facility |

EPIC |

1,500,000 |

1993 |

Scope:

- E – Engineering

- P – Procurement

- C – Construction

- I – Installation

- PM – Project Management

- Ct – Consultancy

- M – Maintenance

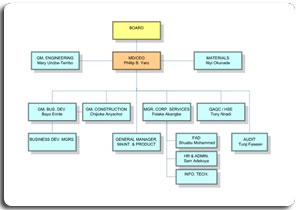

Executive Contact

Engr. Mary Unobe-Tembo

General Manager, Engineering

4th Floor, Union Marble House,

1, Alfred Rewane Road, Falomo,

Ikoyi, Lagos, Nigeria.

Phone: (+234) 1 474 0828; 1 463 0217 – 8

Fax: (+234) 1 269 4549

E-mail: mtembo@cakasa.com |

| Ver más: |

Interview with Engr. Yaro P. Balami And Interview with Engr. Yaro P. Balami And

Engr. (Mrs.) Mary Unobe-Tembo,MD/Ceo And Gm Cakasa Nigeria) Company Limited...read more!

|

|